Sprinklers Approved for use with Foam Concentrate

The Low Expansion Synthetic Fluorine-Free Foam (SFFF) system consists of various FM Approved and/or UL Listed components to create a complete package for flammable liquid protection. Included in this package are pendent and upright foam sprinklers, which are FM Approved non-aspirating foam discharge devices in both closed and open sprinkler configurations!

Foam Chamber

The Low Expansion Synthetic Fluorine-Free Foam (SFFF) system consists of various FM Approved and/or UL Listed components to create a complete package for protecting flammable liquids. Included in this package is a foam chamber, suitable for the protection of fixed roof-mounted tanks and used as a low-expansion Type II discharge device (as defined by NFPA 11), with an approved and/or listed foam concentrate and proportioning device.

Foam chambers are designed to apply an expanding foam blanket over the surface of a flammable liquid fire as gently as possible to achieve extinguishment and/or vapor suppression. Typical applications include manufacturing plants, large tank farms, oil refineries, and chemical plants. Foam chambers are UL listed with USP concentrate (Hydrocarbons only) at an application rate of 0.1 gpm/sq ft.

Foam Oscillating Unit

The Low Expansion Synthetic Fluorine-Free Foam (SFFF) system consists of various FM-Approved and/or UL-Listed components to create a complete package for protecting against flammable liquids. Included in this package is a foam monitor, which effectively covers a wide application area with water or foam solution!

Manual or oscillating monitors are typically part of a fixed flood or flow control system, but they can also be supplied locally via fire hydrant or hose supply, and can also be mounted on mobile trailers for greater versatility in challenging fire scenarios. Foam monitors are used in areas such as flammable liquid storage tank farms, loading racks, incineration facilities, recycling plants, aircraft hangars, helidecks, and dock protection applications.

Viking offers Model VMT, VMH, VMW Monitors, Model VNN, VNS Nozzles, and Model VSO Oscillating Units.

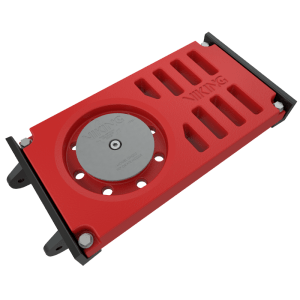

Grate Nozzle Upgrade Kit

The Grate Nozzle Upgrade Kit is intended for use with Viking Grate Nozzles to upgrade the nozzle assembly from the GN200 to the GN202 model.

The FM Approved Model GN202 Grate Nozzle is available in 90°, 180° and 360° variations, with widths of 555 mm, 20” and 26” to meet design requirements.

The grate nozzle is a low-expansion foam discharge device that produces a uniform discharge pattern with a maximum spacing of 50ʹ x 25ʹ (15.2 m x 7.6 m), offering effective flammable liquid protection. The nozzle is installed flush with the floor of the shelter area within the discharge trench. The companion discharge trench grate is specially engineered to accept the grate nozzle and serves as a discharge trench cover.

Grate Nozzle Model GN202

The Low Expansion Synthetic Fluorine-Free Foam (SFFF) system consists of various FM Approved and/or UL Listed components to create a complete package. Included in this package is the FM Approved Model GN202 Grate Nozzle, available in 90°, 180° and 360° variations, in 555 mm, 20” and 26” widths to meet design requirements.

The grate nozzle is a low-expansion foam discharge device that produces a uniform discharge pattern with a maximum spacing of 50ʹ x 25ʹ (15.2 m x 7.6 m), which offers efficient flammable liquid protection. The nozzle is installed flush with the floor of the shelter area within the discharge trench. The companion discharge trench grate is specially engineered to accept the grate nozzle and serves as a discharge trench cover.

VFM Model Foam Maker

The Low Expansion Synthetic Fluorine-Free Foam (SFFF) system consists of various FM Approved and/or UL Listed components to create a complete package for flammable liquid protection. Included in this package is a foam generator, which is an in-line, fixed foam aspirator device used in low-expansion foam discharge applications to protect pond levees and other low-level discharge applications.

The foam maker is FM approved with 3% USP concentrate (Hydrocarbons only) at an application rate of 0.1 gpm/square foot, and with ARK concentrate (Polar solvents & Hydrocarbons) at the following application rates:

- Ethanol 0.16 gpm/square meter.

- Hydrocarbons & Acetone 0.2 gpm/square meter.

- Isopropil Alkohol (IPA) 0,25 gpm/sq ft.

- Our Products

- Fire Protection Systems & Products

- Sales & Inquiries