Fires can occur at any time, and within minutes, they can destroy an entire building. Therefore, a reliable fire protection system is a vital necessity—and one of its most important components is fire pumps.

The fire pump (fire pump) works to ensure water pressure in the hydrant or sprinkler system remains stable, even when the city’s water network is inadequate. This article will comprehensively discuss the functions, types, how they work, and tips for choosing the right fire pump.

What Is a Fire Pumps and Why Is It Important?

The fire pump isa mechanical device used to increase water pressureinto the hydrant or sprinkler system’s piping network. Its function is to ensure water can reach the entire fire area, especially in high-rise buildings or large areas like factories.

Without a fire pump, water from the tank or reservoir will not have enough pressure to reach the hydrant or sprinkler nozzles on the upper floors.

Main Functions:

- Provides consistent water pressure during fires.

- Supports hydrant and sprinkler systems to function optimally.

- Address low pressure from the main water source.

- Ensure water flow meets standards NFPA 20 And SNI.

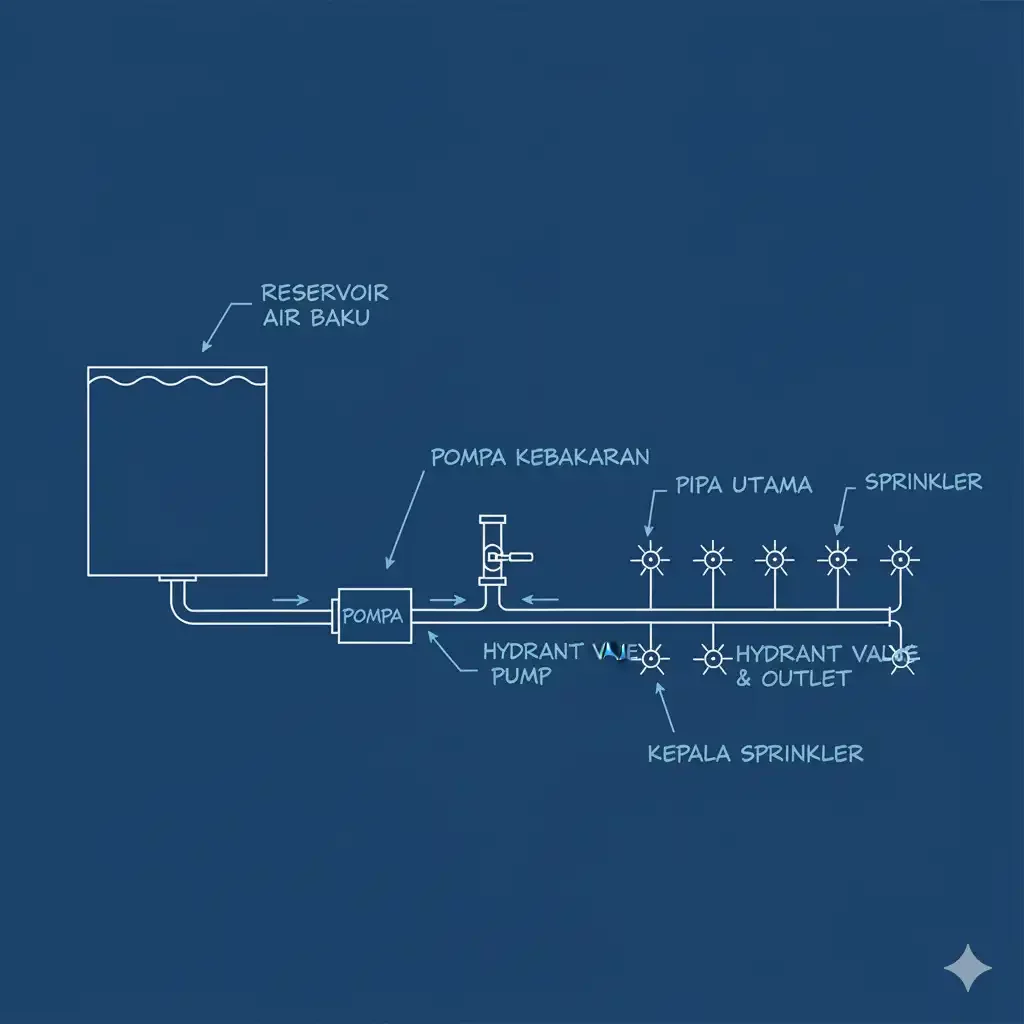

The Relationship between the Pump and the Hydrant and Sprinkler System

The fire pump isheart hydrant systemWhen water pressure drops due to a hydrant or sprinkler activation, the pump automatically turns on to maintain pressure.

Types of Fire Pumps

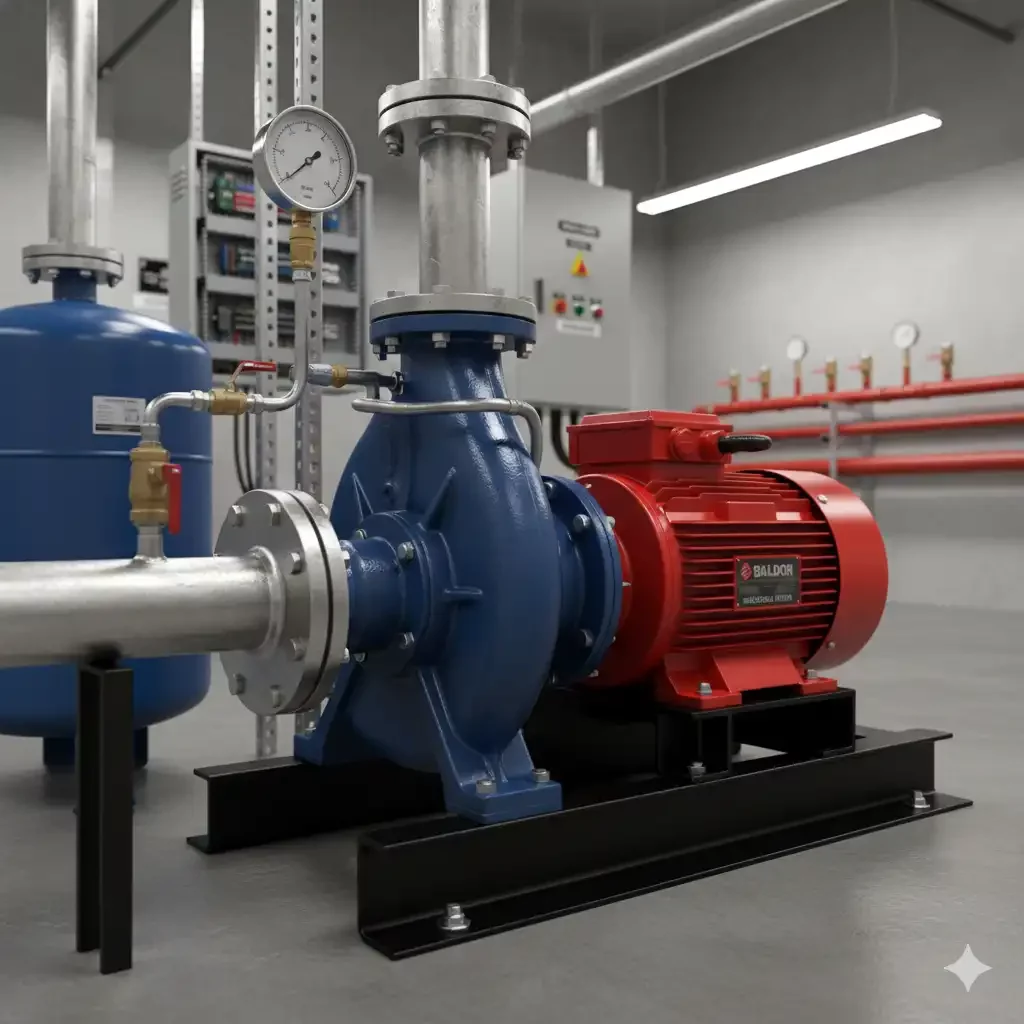

1. Electric Fire Pump

Uses an electric motor as the primary drive. Commonly used in commercial buildings with a stable power supply.

Advantages:

- Quiet and efficient operation.

- Low maintenance costs.

Disadvantages: - Does not work if the power supply goes out without a backup generator.

2. Diesel Fire Pump

Using a diesel engine so thatstill works when the power goes out. Usually equipped with a separate diesel tank.

Advantages:

- Reliable in emergencies.

- Suitable for industrial facilities and large factories.

Disadvantages: - Needs regular maintenance and fuel checks.

3. Jockey Pump

A small pump that works maintain system pressureso that the main pump does not turn on frequently.

Advantages:

- Saves the life of the main pump.

- Energy saving.

Disadvantages: - Not designed for direct fire.

How a Fire Pumps System Works

The system works automatically based on pressure switch.

When the water pressure drops below the normal limit (usually 7–10 bar), jockey pump active first. If the pressure continues to drop, main pump (electric/diesel)automatically turns on. Once the pressure returns to normal, the system stops.

This flow is directed to hydrant pillar, sprinkler, atau hose reel, ensuring a constant water supply during outages.

Main Components of a Fire Pumps System

- Controller Panel– The brain of the system to control automatic ignition.

- Gate Valve & Check Valve– Regulates water flow and prevents back pressure.

- Flow Meter & Pressure Gauge– Measuring water pressure and volume.

- Header (Suction & Discharge)– The main water line in and out of the pump.

- Pressure Switch– Automation trigger sensor.

Guide to Choosing the Right Fire Pumps

- Calculate pump capacity and head based on the height and length of the pipe.

- Select the pump type according to power conditions or backup needs (diesel).

- Pay attention to certification (UL/FM/SNI) for safety and reliability.

- Ensure after-sales service is available.

Adiwarna can help to do that fire pump design and selection calculations according to your project needs.

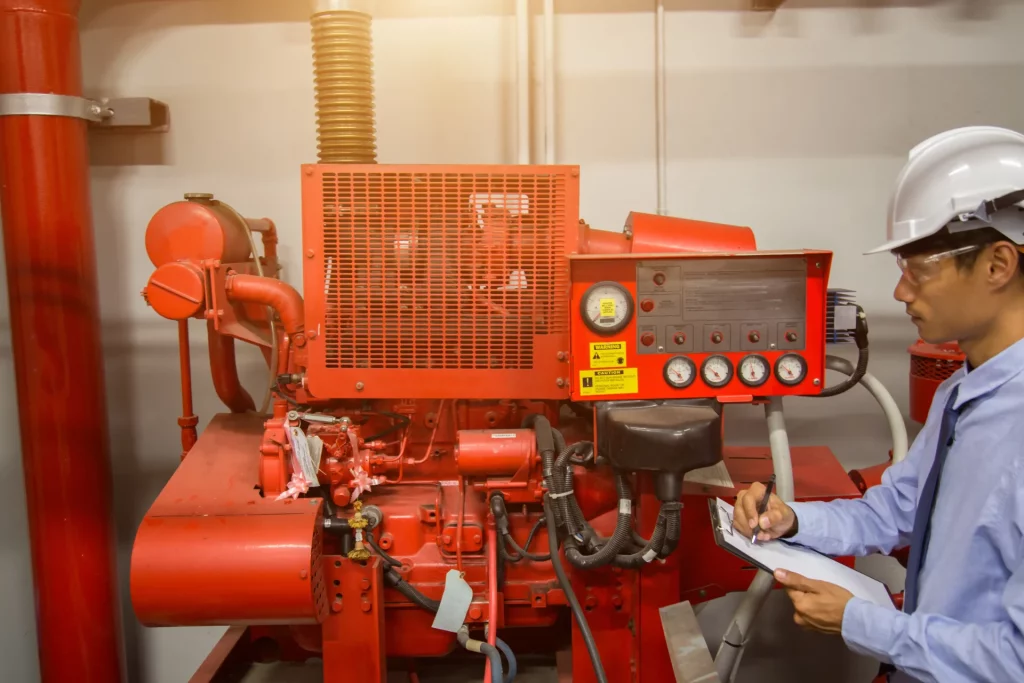

Fire Pump Maintenance and Testing

To keep the pump ready for use:

- Do weekly test (run test 10–15 minutes).

- Check fuel & oil levels on diesel pumps.

- Record the pressure and flow results for each test.

- Clean the filter and pump chamber from dust.

- Do an overhaul every 2 years.

Signs that the pump needs servicing: decreased pressure, abnormal noise, high vibration, or pipe leaks.

Fire Pump Standards and Regulations

In Indonesia, fire pump installations follow:

- SNI 03-6574:2001

- NFPA 20 (International Standard)

- Regulation of the Minister of Public Works and Public Housing concerning Building Safety

Following these standards ensures your system legally and insurance recognized.

Integrated Fire Pump System Solution from Adiwarna

Adiwarna provides comprehensive solutions:

- Pump design and specification consultation.

- Installation and testing of fire pump systems.

- Periodic maintenance and user training.

Make sure your building’s fire protection system is functioning optimally.

🔥 Consult your fire pump needs with Adiwarna today!

FAQ

1. What is the difference between diesel and electric pumps?

Diesel pumps work without electricity, while electric pumps depend on the main electricity supply.

2. Can the fire pump be used for regular water?

Not recommended, as this pump is specifically designed for emergency conditions.

3. How often are fire pumps tested?

Every week (light-on test) and every year (full performance test).

Conclusion

Fire pumps are a vital component of any fire protection system. Without adequate water pressure, hydrant and sprinkler systems will not function optimally.

By choosing a quality pump and performing regular maintenance, you protect your assets, your occupants, and ensure long-term safety.

Adiwarna present to providean efficient, standard-compliant fire pump system solution that is ready to respond whenever needed.