Building the Foundation of a Reliable Fire Protection System

An advanced fire suppression system like Fire-Eater Inergen® is more than just its extinguishing gas. Its superior performance, speed, and reliability depend on every single piece of hardware that makes up the system. Fire-Eater designs and manufactures its own range of High-Pressure Gas Components, ensuring that every part works in perfect harmony to deliver uncompromising protection.

Let’s break down the anatomy of this world-class fire suppression system.

Key High-Pressure Gas Components and Their Functions

Each part plays a critical role in storing, directing, and discharging the extinguishing agent with precision.

- High-Pressure Cylinders: These are the storage vessels for the Inergen® gas. Made from high-strength steel, these cylinders are designed to safely contain the gas at high pressures (e.g., 200 or 300 bar), ensuring a large volume of gas can be stored in a relatively small space.

- Cylinder Valves: Mounted atop each cylinder, these valves are the main “gatekeepers.” Fire-Eater valves are designed to be fast-acting, opening in a fraction of a second upon activation to release the gas. Each valve is equipped with a pressure gauge for easy visual inspection.

- Actuators: These are the triggers that open the cylinder valves. They can be solenoid (electric), pneumatic (air pressure), or manual actuators. Upon receiving a signal from the control panel, the actuator physically opens the main valve.

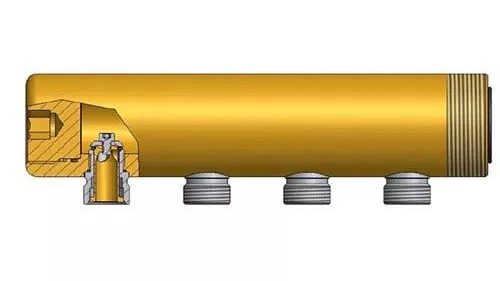

- Manifolds: A robust collector pipe where multiple cylinders are joined together into a single “bank.” The manifold ensures that the gas flow from all cylinders can be discharged simultaneously and directed into one main pipe run.

- Selector Valves: In a Multi-Zone system, selector valves (like the SV22 model) act as “traffic controllers,” directing the entire flow of gas only to the specific room that is on fire.

- Nozzles: This is the final component in the delivery path. Fire-Eater nozzles are specially engineered to distribute the Inergen® gas evenly throughout the protected space in a 360-degree pattern, ensuring the extinguishing concentration is rapidly achieved in every corner.

High-Pressure Gas Components Engineered for the Highest Performance

- Quality and Certification: All high-pressure components from Fire-Eater are rigorously tested and certified by leading international bodies, such as VdS. This is your guarantee that every part meets the highest standards of quality and safety.

- An Integrated System: Fire-Eater doesn’t just sell parts; it provides an integrated system. Every valve, nozzle, and actuator is designed to work seamlessly together, ensuring optimal performance.

In conclusion, the power of a Fire-Eater system lies in the engineering details of its components. By building every part to the highest standards of precision and quality, Fire-Eater creates a fire protection system that is not only powerful but, above all, incredibly reliable.