AFFF is an abbreviation of Aqueous Film Forming Foam, namely the type THE bus APPEARS Water-based fire extinguisher that is effective for extinguishing fires on liquid and solid fuels.

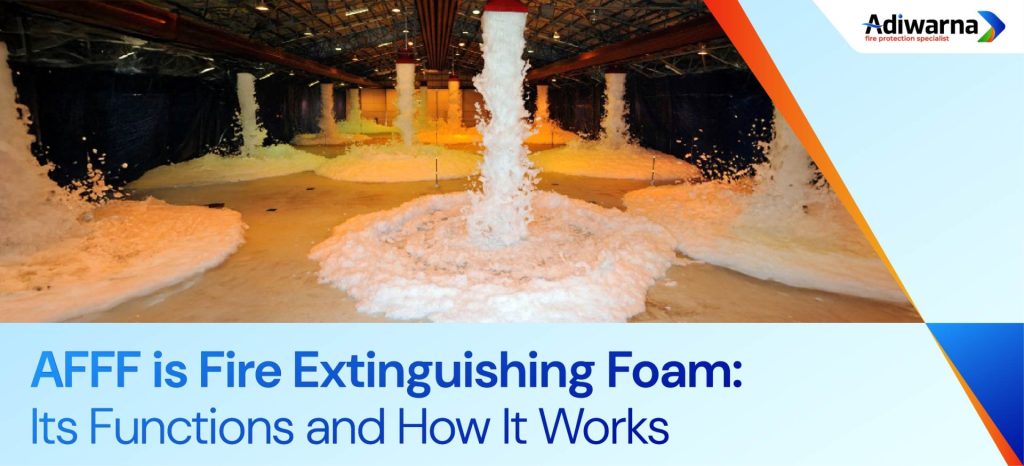

This foam is used in modern fire protection systems due to its rapid ability to control fire and prevent further spread. AFFF is widely used in industrial facilities, fuel storage areas, airports, and even ships.

This article will discuss in full the meaning, function, and how AFFF works in fighting fires.

What is AFFF (Aqueous Film Forming Foam)

AFFF is a fire-fighting foam composed of a mixture of water, hydrocarbon surfactants, and fluorocarbon surfactants. This composition allows AFFF to form a thin film on the surface of flammable liquid fuels such as gasoline, diesel, and oil.

The main purpose of forming this layer is to stop oxygen access to the fuel and suppress vapors that could trigger a new flame.

AFFF works effectively in a variety of fire scenarios, including class A fires (solid materials such as wood and paper) and class B fires (flammable liquids). In special versions such as AR-AFFF (Alcohol-Resistant AFFF), this foam is also able to fight fires caused by polar liquids such as alcohol.

AFFF is function

The primary function of AFFF is as a fast and efficient fire extinguishing agent. Some specific functions of AFFF include:

- Extinguishing liquid fuel fires: This foam is very effective in controlling fires caused by gasoline, kerosene, and similar liquids.

- Isolating fuel from oxygen: The film layer formed by AFFF covers the fuel so that oxygen cannot reach the surface, which inhibits the combustion process.

- Cooling the burned area: The water content in the foam helps lower the surface temperature, preventing re-ignition and reducing the risk of fire spreading.

- Reduces fuel vapors: In addition to blocking oxygen, the film also suppresses fuel vapors, which is an important factor in the re-ignition process.

These functions make AFFF the primary choice in automatic fire extinguishing systems such as hydrants, sprinklers, and APAR (Light Fire Extinguishers).

How AFFF is Works in Fighting Fires

The Process of Forming a Film Layer on the Fuel Surface

When AFFF is sprayed onto a burning area, the foam will flow and spread over the surface of the liquid fuel.

Its chemical composition allows it to form a very thin yet effective aqueous film that blocks direct contact between oxygen and fuel. This is the essence of AFFF’s effectiveness: it stops the combustion process by isolating two essential elements: fuel and oxygen.

This layer acts like a protective blanket that tightly seals the fuel and prevents evaporation, so the fire loses its energy source and goes out more quickly.

Cooling and Oxygen Separation Mechanism

In addition to forming a film, AFFF contains a large amount of water, which absorbs heat from the fire area. This cooling process is essential to lower the surface temperature below the flash point, preventing re-ignition.

Moreover, the foam also forms a physical barrier between the fuel and the surrounding air. Because oxygen unable to reach the fuel surface, the combustion reaction stops.

The combination of cooling and oxygen separation makes AFFF a highly effective solution for completely extinguishing fires and preventing them from spreading.

AFFF is a highly efficient foam-based fire extinguishing solution for class A and B fires. With its ability to form a protective film and strong cooling mechanism, AFFF works quickly to stop the fire and prevent further spread of the fire.

As a specialist fire protection contractor, Adiwarna provides AFFF-based extinguishing system solutions specifically designed to meet the needs of industrial and commercial facilities. Using quality products and experienced technical support, Adiwarna ensures your fire protection system performs optimally when needed.